The Surface Acoustic Wave - SAW - technology used in

the Passive Wireless Temperature Sensor (SAW)

I. Introduction

Các điểm · nóng (hot-spot) bên trong tủ điện dễ bị phát nhiệt và PD

In low-voltage to high-voltage large-capacity electrical equipment, critical points in switches, electrical cabinets, transformers, generators and other electrical system equipment are susceptible to damage if not closely monitored and controlled.

Increased load current, aging equipment after a long time of operation will cause the temperature of components in electrical equipment to rise, the higher the temperature will cause rapid degradation of the insulation and metal contacts. If this process is repeated for a long time, it will cause equipment fire and explosion incidents, causing heavy economic damage and loss of safety for people.

Loss of insulating materials due to damaged or polluted insulation causes electrical discharges between live components in the equipment. Continuous discharge can cause fire and explosion incidents in electrical cabinets, transformers ... This is a particularly important issue related to the development of the economy in which the demand for electricity is always needed.

Currently, to detect the heat-generating points of conductors in electrical systems, traditional temperature-checking methods such as infrared cameras or infrared heat-emitting devices are often used. On the lines, these devices are used to check the heat generation of the conductors / conductors at the joints, pins, connections; In a substation, a device is used to detect heat generation of the device at contact jaws, pole clamps, and jaws. In order to detect heat-generating points in closed cabinets such as breakers, distribution cabinets, these cabinets must be designed with open-hole enclosures to enable the infrared detector to check the heat generation of the equipment. be inside. This has a limitation if the heat-generating sites that are not directly exposed to the infrared rays of the scanner cannot be detected..

The weakness of other solution

|

IR CAMERA |

Tradditional Sensors |

|

· • The temperature cannot be measured in hidden deep inside the device. · • High investment costs. · • The picture may be distorted due to dust ... · • Cannot monitor the temperature continuously. |

· • Cost of battery maintenance and replacement. · • Limited access to equipment for battery replacement. · • Impact on the environment. · • Takes time to install. |

The conventional temperature monitoring solutions above are quite expensive and less effective. SENSeOR (France) has researched and developed surface acoustic wave (SAW) technology to offer compact wireless passive sensors, integrated into an innovative and advanced surveillance platform for the monitor electrical equipment and industrial machines. Besides, SENSeOR also integrates partial discharge detection (PD) to monitor equipment, ensuring that the equipment operates in the best condition.

SAW sensors use crystal sensor components, based on surface acoustic wave technology and piezoelectric phenomenon. The piezoelectric phenomenon is the linear electromechanical interaction between mechanical and electrical properties in crystalline materials, which is a reversible process..

II. The solution

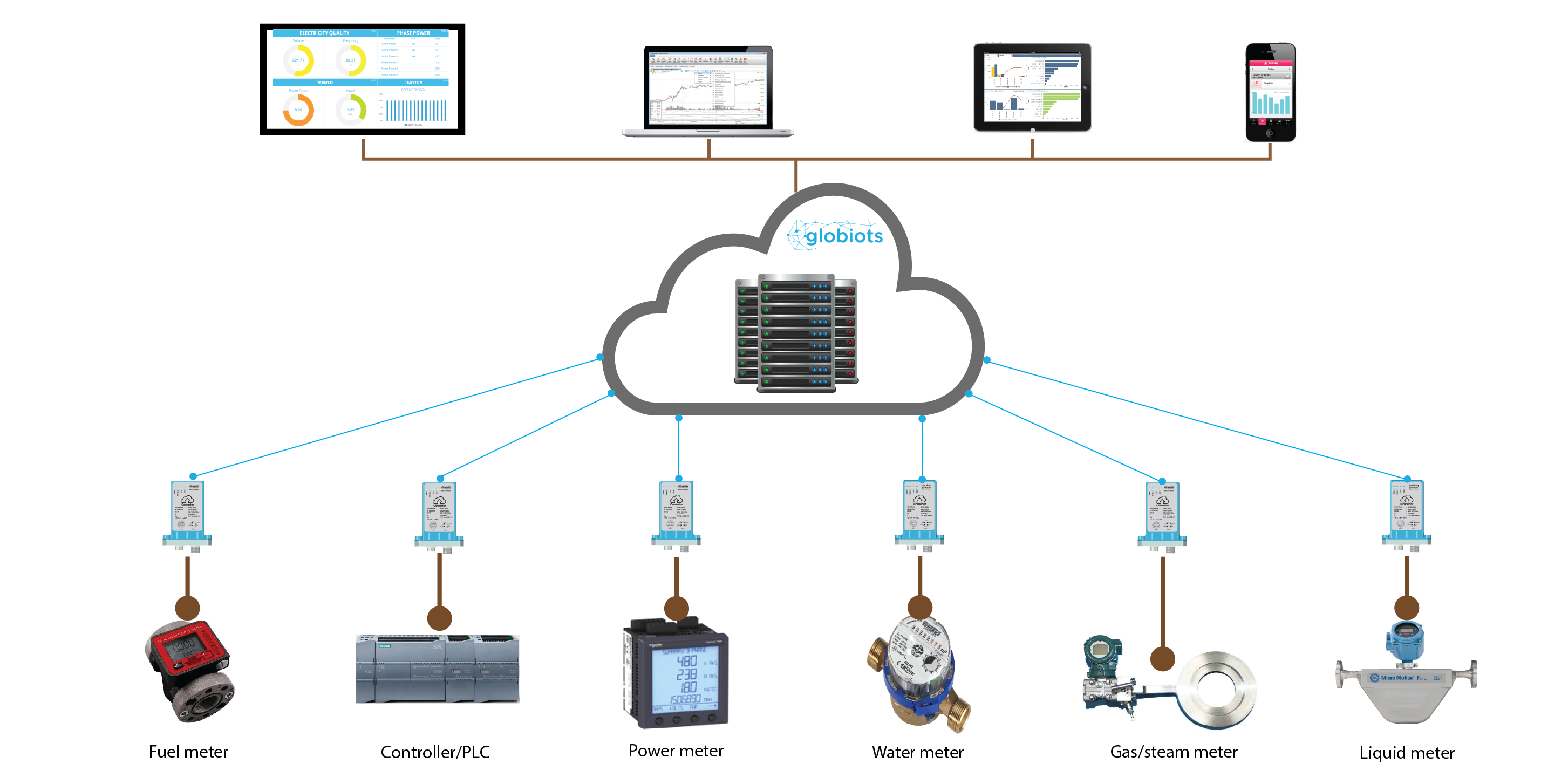

SENSeOR wireless temperature monitoring system realizes online temperature monitoring, real-time alarm, data recording for trend analysis of temperature.

Utilize dynamic load monitoring technology and condition-based maintenance of critical positions in power transmission and distribution systems. The wireless passive temperature sensor is specially designed for use in high current and voltage (545kV - 20kA) environments. Quick and easy installation in electrical cabinets.

The system instrumented with:

- Transceiver (Platform).

- PD probes antennas.

- SAW tempeature sensors.

- Ambient temp & humidity sensor.

OPERATIONAL PRINCIPLE OF TEMPERATURE MONITORING

1. The transceiver sends an electromagnetic signal to the sensor (~ mono-static RADAR).

2. The antenna of the sensor captures the signal, IDT on the surface of a

piezoelectric substrate - Quartz – converts it into a Surface Acoustic Wave and reflects these modified signals back to the transceiver.

3. The transceiver computes, processes and translates the signal into an exploitable data: temperature from -25 to 150°C with an accuracy of +/-2°C full range.

4. The data is sent to the local HMI or remotely to a Cloud.

5. Alarms can be set of custom thresholds.

6. Temperature and PD sequence

PARTIAL DISCHARGE

· Small electrical discharges which appear on the insulation of an electrical equipment.

· PD is generated at a specific point where the dielectric strength of the insulation material can not withstand properly the electric field.

· PD activity is progressive and is caused by cracks, cavities or contamination of the insulation material caused by aging, deterioration or inadequate environmental and operating conditions.

· In case of the PD activity is not detected promptly -> failures in the equipment … arc flash!.

- SENSeOR proposes a low cost Partial Discharge Detection (>100pC) solution based on UHF method by usingthe same probe antennas as for the SAW sensors interrogation.

- SENSeOR proposed a Partial Discharge Detection solution based on UHF method by performing a 24/7 Trend Monitoring

- Same Probe antennas sensitive to a PD event and able to communicate with the SAW temperature sensor

OPERATIONAL PRINCIPLE OF PD DETECTION

III. ADVANTAGES

- Solution gives access to all critical points, stability, cost

- Flexible positioning of the sensors inside the cubicle, directly on the hot spots.

- Partial Discharge trend monitoring, multi-sensing platform.

- Temperature and ambient humidity monitoring.

- Customizing multi-input and multi-output.

V.T.E.C.H ELECTRICAL TECHNOLOGY CO., LTD

V.T.E.C.H ELECTRICAL TECHNOLOGY CO., LTD