1. How do thermal cameras work in a security situation?

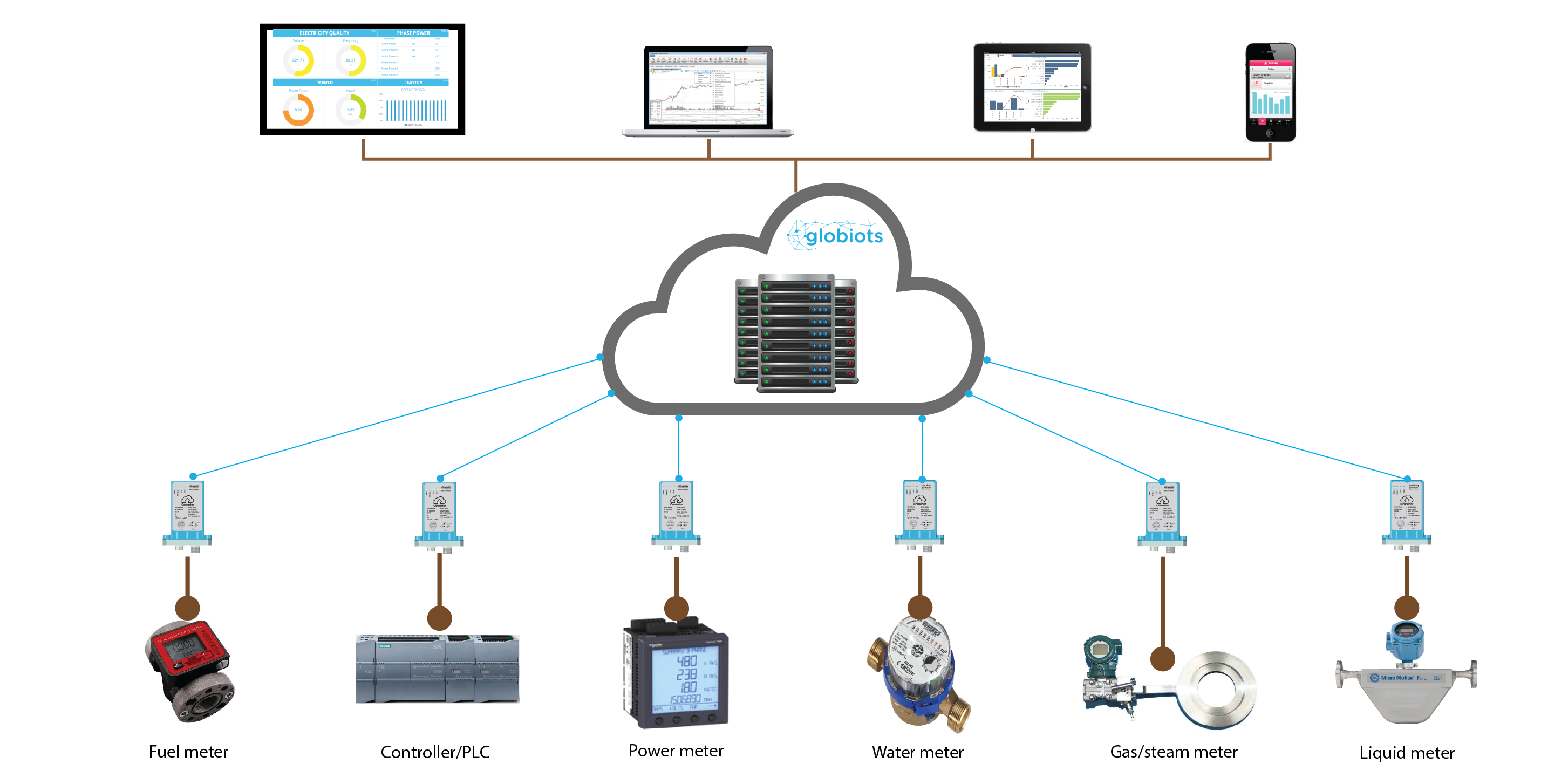

Thermal Imaging Network Monitoring Systems are based on using network protocols WAN and/or LAN. It can function as a separate monitoring system, or be incorporated into a variety of already existing systems within a facility; this includes online monitoring systems, digital image monitoring systems and security fire alarm systems. These systems generally consist of dual-channel, all-weather monitoring cameras (including high-performance infrared imaging with visual CCD camera) and the corresponding network of computers. The system uses advanced computer data compression and network transmission technologies. Using standard RJ45 Ethernet network cable, free level or central control monitoring can be enabled (one-to-more and more-to-one inspection). Only one network cable is needed to change the camera settings and features, which include over-temperature alarm, auto-video recording and automatically generating fault reports while monitoring the daily work in the distance. Innovative image fusion technology allows users to combine the infrared image and the CCD image aiding to identify the fault position rapidly.

The system is equipped with powerful real-time analysis software. Its functions could meet a variety of online real-time monitoring and scientific experiments for different users. In addition, the software is customized, and the software development kit SDK is provided to the user for secondary development.

2. In what type of surveillance areas should there be infrared cameras?

Night and day, thermal imaging systems detect intruders where conventional CCTV systems fail. Requiring no external lighting, thermal imaging provides vivid, high-contrast video of intruders, even when hidden by obscurants such as fog, smoke, steam, or lack of ambient light. This makes thermal imaging ideal for in-plant surveillance, perimeter monitoring, and high-value asset protection

Infrared cameras can be used to monitor extended areas of open water, shoreline, ports, harbours, and dock facilities.

Combine long-range and mid-range thermal imaging systems for comprehensive surveillance of nuclear power plants, airports, bridges, petrochemical facilities, pipelines, and cargo terminals. Maintain perimeter integrity with a network of camera systems that provides uninterrupted detection of intruders 24 hours a day. Select from a wide range of handheld and platform-mounted systems ideal for factories, airports, commercial complexes, and private residences.

JKZ365 | Process Control

JKZ365

400x300/640x512 IR Detector

Standalone Operation

Digital/Thermal/AI Technology

Temperature Alarms : 16x Area boxes ,2x Lines or 20x Spots

17 Colour Palettes

Optional Fixed Lenses: 8/15/25mm

Process Control Camera for Power Industry

The JKZ365 is SATIR newest fixed camera model. It has been designed for the Power and Energy Industry to monitor power and sub stations. It combines digital and thermal technology to deliver excellent imaging capabilities. It also includes some AI technology settings which gives more options to activate temperature alarms that can alert plant enginneers of any over-heating or issues. For example, once the alarm has been activated then the zoom on the digital camera can allow easy identification of the potential defective component and corrective action can be taken by the plant engineers.

The JKZ365 is a PTZ camera which allow users to monitor a large area with a single camera. Its is ONVIF and CGI compliant which means it can be integrated into a standard CCTV network or on a stand alone network. This makes the JKZ365 a dual use product. it can be used for security at a substation site and also monitor the plant, which makes it the excellent product to purchase at one price point. The JKZ365 allows for SDK intregration which means the product can fit in easily with exisiting plant systems which means the end-user has a bespoke product that meets their needs and requirements.

https://satir.com/product/jkz365-process-control

V.T.E.C.H ELECTRICAL TECHNOLOGY CO., LTD

V.T.E.C.H ELECTRICAL TECHNOLOGY CO., LTD