Intelligent OHL Transmission Line Surveillance Solution

1. About Senter

Overall strength

- Our positioning:IoT solution provider with in Power Electronic Industrial and Telecom Industrial

- Our main customers: State Grid Corporation of China and China Southern Power Grid,China Telecom

- Our sales volume: In China, we have installed 300,000 surveillance monitors, and the annual sales revenue is 59.68 million US dollars

- Our overseas markets: United Arab Emirates, Kuwait, South Africa and Saudi Arabia.

Application Background – Problems:

- OHTL have many towers, long lines and wide adeas, so it is difficult for manpower to reach remote areas and the inspection frequency can not be guaranteed.

- The line equipment has been exposed to the natural environment for a long time and has been attacked by various climatic conditions (storms, floods, ice and snow wind, clouds, pollutions, lightning strikes, sandstorms, etc.)

- Other external force damage (such as construction machinery breaking wires, bird damage, wildfires, etc.)

- Once a fault occurs, it will take a long time to repair the power transmission, which will cause different degrees of loss

- The traditional inspection mode requires a lot of human resources, high cost, low efficiency, and it is difficult to meet the rapidly expanding power grid scale

- Theft issua for Tower and wire cable

Application Background – What does it can do?

Our solution can replace most manual inspection and do the 24h inspection of pictures especially in remote place. As you want to see,you can see in any time for any Tower and transmission line.

At the same time, through the comparison of pictures and Analisis in the database,it will alarm and can reduce the power failure rate and provide industrial efficiency finally.

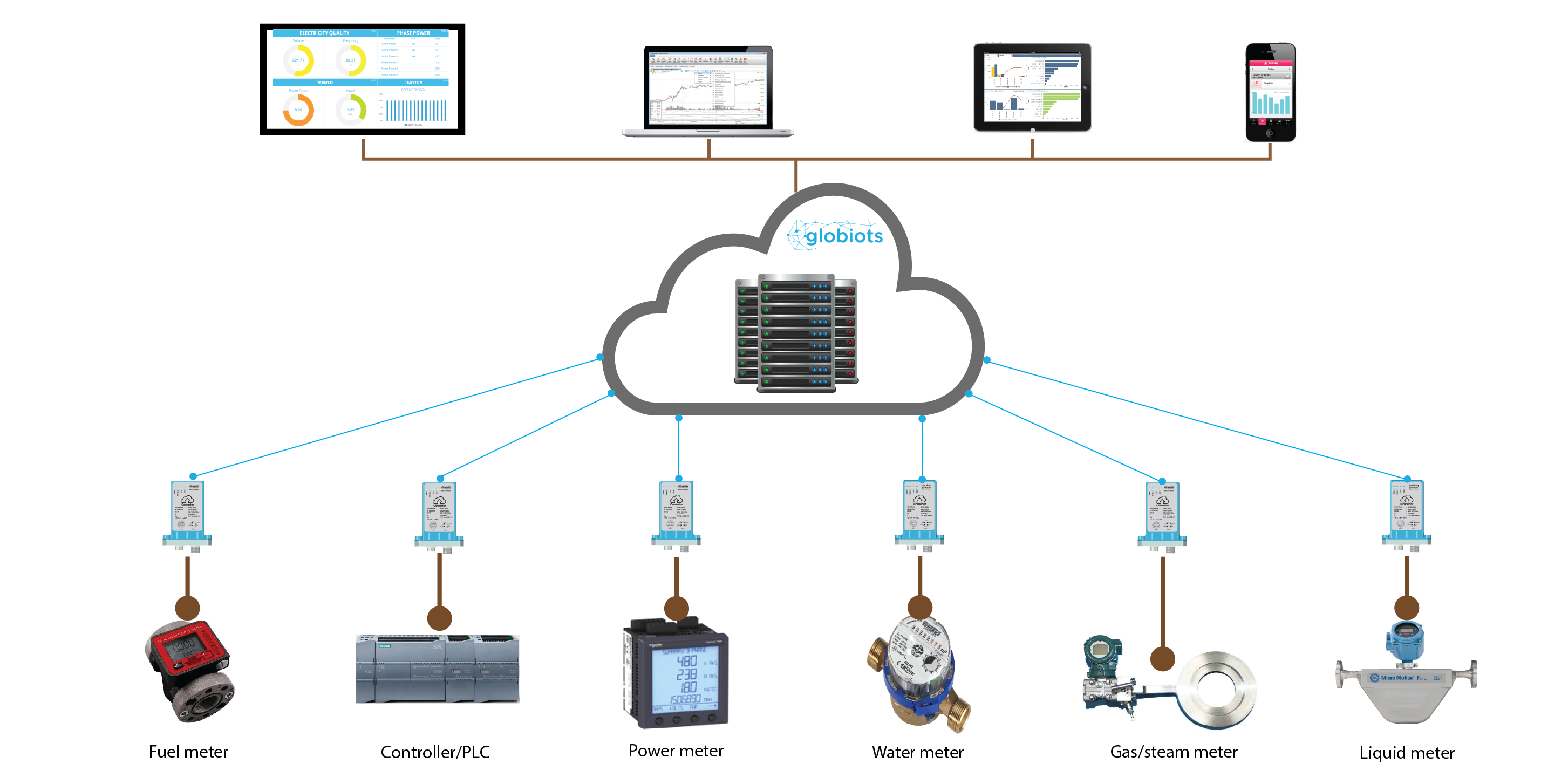

Overall of Surveillance Solution

Intelligent Transmission Line Surveillance Solution, maily include 1. Front-end hardware 2. Algorithm 3.Network Layer 4.Platform,it Aims at holographic perception and intelligent IOT,it realizes intelligent autonomous analysis,Alarm and remote centralized monitoring through a series of terminal products and software products, serves for lean three-dimensional inspection of transmission lines, and realizes multi- dimensional perception of transmission lines.

2. Solutions

Solutions - system block diagram

The overall idea and content of the solution

Solutions – compare other way

We use less than 20% of the cost to solve 80% of the demand pain points, significantly reduce the cost and improve the service life.

First of all, we have a price advantage compared to these traditional patrol methods

Second, our machines do not need legal licenses and professional technicians to operate.

Third, The biggest difference between us and traditional video surveillance is that we have created a mode: Main picture monitoring, supplemented by video for intelligent analysis.

Under the premise of not affecting the inspection efficiency, this greatly improves

the service life and spare duration of the machine.

Solutions - Perception layer-Hardware

Solutions - Perception layer - Hardware and Sensors

Solutions - AI analysis technology for front hardware

Solutions - Application layer - Based on AI Technology

Line channel hidden danger

|

Category |

Identify the target |

|

External force damage to construction machinery |

Crane |

|

Tower crane |

|

|

Pump truck |

|

|

Excavator |

|

|

Dump truck |

|

|

Bulldozer |

|

|

Large trucks |

|

|

Cement trucks |

|

|

Scaffolding |

|

|

Insulated bucket truck |

|

|

Other types of cars |

|

|

Floating objects |

|

|

Trees |

|

|

Active people |

|

|

Smoke, fire |

|

Application layer

The hidden danger of the transmission line itself

|

Category |

Identify the target |

|

Ontology defect |

Insulator missing |

|

Insulator burst |

|

|

Ontology state |

Dancing |

|

Wind deflection |

|

|

Tower vibration |

|

|

Icing |

|

|

Wire sagging |

Platform layer

Video about Zoom functions

Video about taking 15S short video

Process process Example of Anti theft

From finding the damage to shout and Alarm, can finish in two minutes

Automatically play the recording when an alarm occurs

Solutions - Perception layer - Highlight functions

Point Cloud Bullet Camera

Real-time collection of point clouds, unlimited application possibilities

- High- precision lidar: range 450 meters, field of view 70°, ranging error < 3cm, point cloud output ≥ 240,000 points/second

- Compared with the drone point cloud, the average relative error is 0.25 meters

- Three-dimensional ranging hidden: target distance measurement and grading alarm function; tree barrier identification, line sag monitoring, construction or terrain changes, etc.;

- Timed scan + front-end analysis linkage trigger dual mode

Solutions - Network layer

How to solve communication transmission problems in no signal area?

- Deploy wireless bridge terminals on towers in areas with good signal and towers in areas with no signal at the same time.

- The online monitoring equipment is connected to the switch through RG45 cable, and then connected to the network bridge deployed on the tower in the no-signal area through the network cable.

- The wireless network bridge in the no-signal area transmits the online monitoring information to the wireless bridge of the tower in the area with good signal through long-distance wireless, and transmits it back to the monitoring center server through wireless wifi.

Solutions - Application layer - OTher industrial

Our intelligent vision inspection solutions can also be used to prevent external damage to above-ground oil and gas pipelines (construction machinery, human activity).

This greatly reduces the loss and danger caused by leakage, especially due to the combustion and diffusion characteristics of oil and gas (explosive and easy to diffuse), which will have a serious impact on human beings and the environment on which human beings depend.

The principle of intelligent identification is to be able to monitor the possible external force damage in the surrounding environment of the pipeline.

3. Economic and social benefits

Replacing manual inspections with machines,avoid many kinds external damage in advance

The quality of protection is greatly improved

Save money and save human effort, it mean reduce The burden of inspection units on first-line transmission lines inspecitons

V.T.E.C.H ELECTRICAL TECHNOLOGY CO., LTD

V.T.E.C.H ELECTRICAL TECHNOLOGY CO., LTD